Digital dashboards that help you identify deviations and make the right decisions.

Capture your deviations and turn them into improvements

Continuous improvement, Kaizen boards, PDCA and other tools.

All your team’s tasks, neatly organized in one weekly view.

Improve key performance indicators within your specific focus areas with our SQCDP board.

Use the PDCA cycle as a tool to improve both quality and processes

Digital tools for 5S work, recurring audits, and a well-organized workplace.

Visualize KPIs and communicate effectively throughout the entire organization.

Basic project management and activity boards.

Kanban is a powerful method for visualizing, managing, and optimizing workflows.

Digital dashboards for takt time flow with takt time counter and stop time log.

Digital visitor registration provides full control over all planned and executed visits to your business.

AP&T provides metal and fiber-forming companies worldwide with advanced production systems, standalone automation solutions, servo-hydraulic presses, and heat treatment equipment. Building on its strong technical expertise, the company naturally took the step toward digitizing daily operations. By replacing manual routines with Boards on Fire’s digital solution, AP&T has created a more efficient, consistent, and transparent process, laying the foundation for even more impactful global improvement initiatives.

As a fully responsible partner, One Responsible Partner®, AP&T contributes to developing its customers’ businesses through industry-leading expertise, innovative technology, and sustainable, high-performance solutions that remain profitable throughout their lifecycle. AP&T is represented with sales and service operations in Europe, Asia, and North America, while its headquarters, R&D, and most of its manufacturing are based in Sweden. Since 2009, AP&T has been part of Fairford Holdings.

For many years, AP&T operated according to Lean principles for daily management, initially using standard whiteboards. During the pandemic, this approach shifted to an Excel-based solution within Microsoft Teams, where the collection and consolidation of key information and metrics were handled manually. While functional, this method created challenges: notes were often not stored adequately in the system and were inaccessible to most employees, deviations risked not being aggregated to the correct level, and duplicate entries sometimes appeared. Additionally, several company units were missing from the system, an issue they wanted to resolve.

About a year ago, the production leadership team launched a global initiative to improve the pulse and improvement structure, strengthen communication and reporting, and ensure a comprehensive overview of the entire organization in a single tool. In this context, they discovered Boards on Fire and immediately recognized its potential.

Positive recommendations from their partners, Part Development, and a site visit to Väderstad—who had been using Boards on Fire for several years—provided a clear picture of how the tool works in practice. AP&T subsequently decided to implement it themselves. The decision was driven not only by the site visit but also by the system’s flexibility to adapt to operational needs and the positive impression of Boards on Fire as a company, offering fast, efficient, and reliable support.

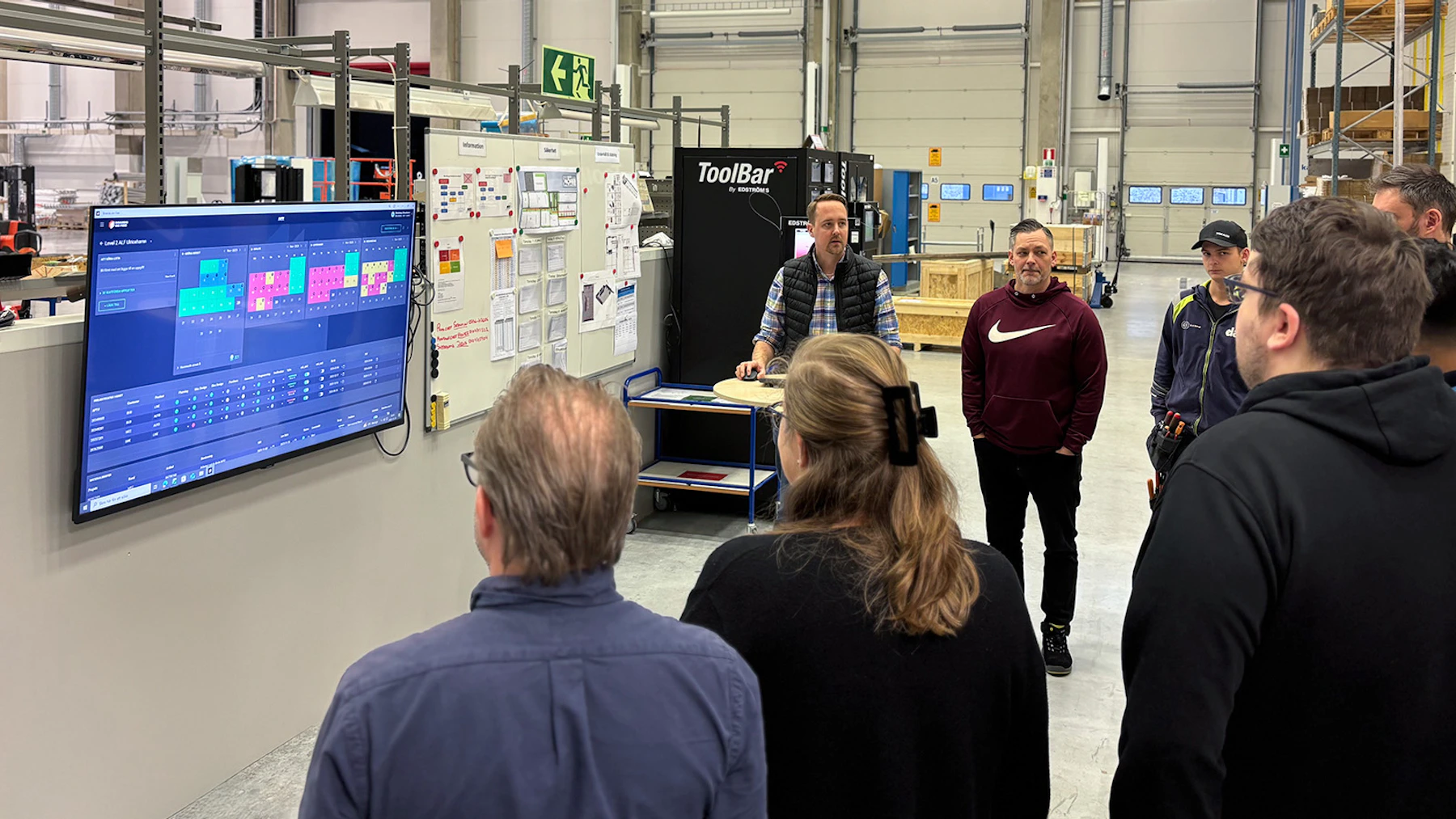

Once AP&T decided to implement Boards on Fire, the system was up and running quickly, thanks to the dedication of Linus Hall, Manager of Planning, Logistics & Spare Parts, who was responsible for creating an environment tailored to the company’s needs.

"The transition to Boards on Fire’s digital daily management solution has been very smooth. Certainly, it required preparation and effort, but it never felt overwhelming," says Martin Klasson, Quality and Sustainability Manager at AP&T Group.

The existing structure and work processes for key metrics and information made the transition much easier. The system could be built on existing data, and employees were familiar with the workflows, reducing learning time and the risk of errors. Additionally, many team members already had experience with the previous routines and were accustomed to working with key metrics in practice. This familiarity helped engage the team in the change, as they could see the connection between the new digital tool and the processes that already worked.

During implementation, Boards were created for all parts of AP&T’s global organization and tailored to each process’s needs. Department heads, with Linus’s support, could also add items to their daily pulse that didn’t necessarily need to be aggregated to higher decision levels. "This has allowed us to work more efficiently across the organization," says Martin. Departments can now conduct both internal follow-ups and cross-functional reviews in a single system.

Since the system was introduced, pulse work can be carried out globally. Previously, production managers had to call each other to align on key metrics and KPIs before presenting them to their teams. With Boards on Fire, this is now a thing of the past, everyone has access to the same information at the same time.

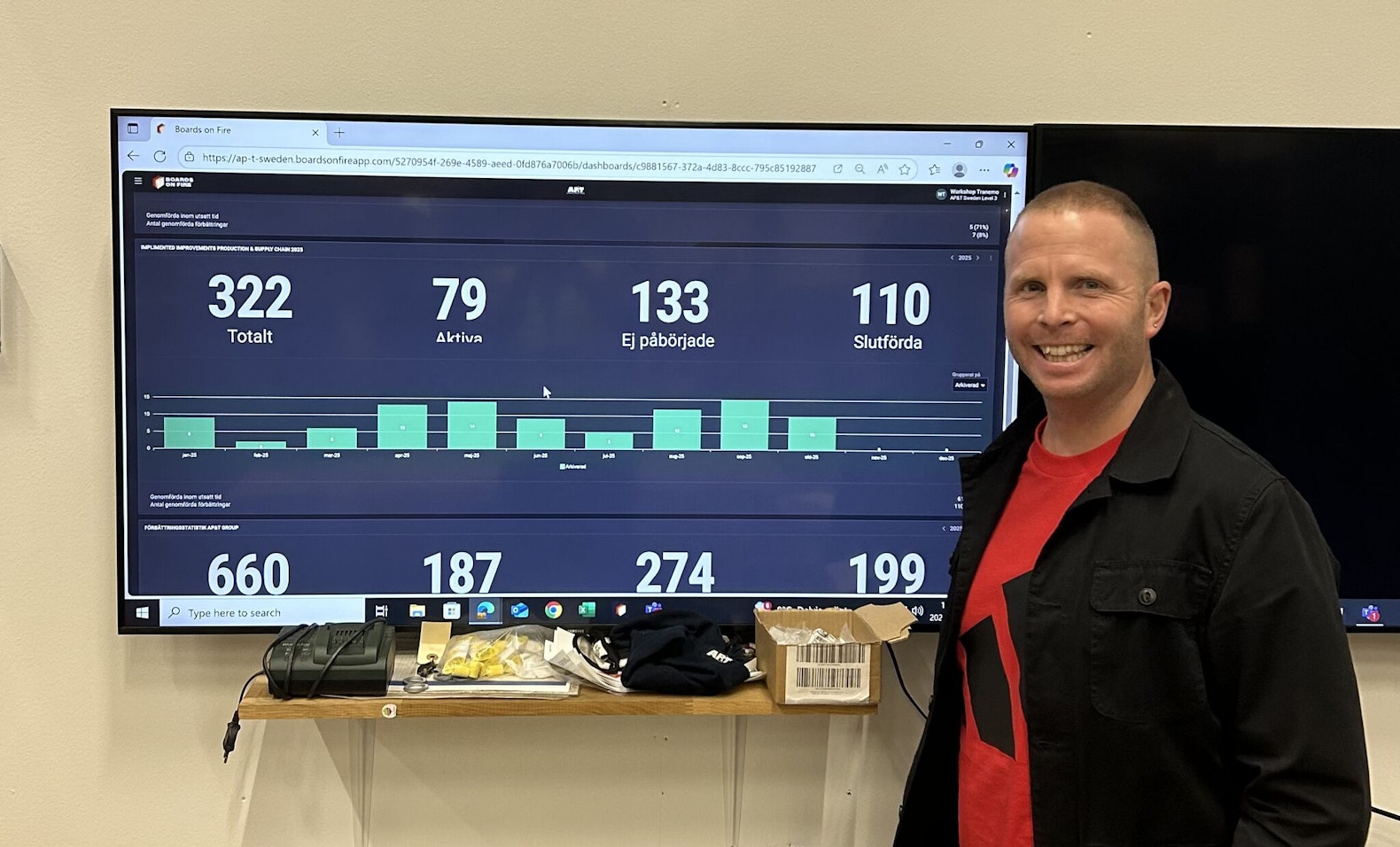

Deviations can also be easily identified, managed, and followed up in a structured way, regardless of whether they occur in Tranemo or Shanghai. The system has also made improvement work smoother across all departments, thanks to its simplicity in tracking and delegating tasks. Since its introduction, AP&T has recorded over 900 deviations, of which 450 have been implemented, while the remainder were discarded as irrelevant.

The features teams have found most valuable are the ability to list and assign tasks, to easily aggregate information across different boards, and the improvement module, which is structured based on the company’s previous training. Overall, Boards on Fire has become an invaluable support in all aspects of daily management, Martin explains.

Employees have embraced Boards on Fire, primarily due to the ability to consolidate all data in one place.

"The process has become more visual and user-friendly for many with Boards on Fire, both when managing our pulse and when using the improvement module," Martin says.

Martin also notes that implementation has strengthened routines around pulse meetings and improvement work. While this initially met some resistance, he sees it as an opportunity to further develop both operations and production by creating clearer processes, enhancing follow-up, and fostering a continuous improvement culture.

Looking ahead, AP&T is integrating Boards on Fire’s modules for disruptions and deviations, enabling a more structured and streamlined approach to managing problems and issues.

Free web demo